Storage tanks plays an important role in petrochemical or natural gas plants for supplying oil, gas under high heat, high pressure.

In recent years, oil suppliers began to realize the risk of leakage from bottom plate is constantly rising due to corrosion environment and decrepit equipment. Pulsed Eddy Current is able to detect corrosion located at the opposite side of the plate, ensuring the defect depth is correctly quantified. This time, we had a great chance to assess the condition of storage tank plate with 6mm thick.

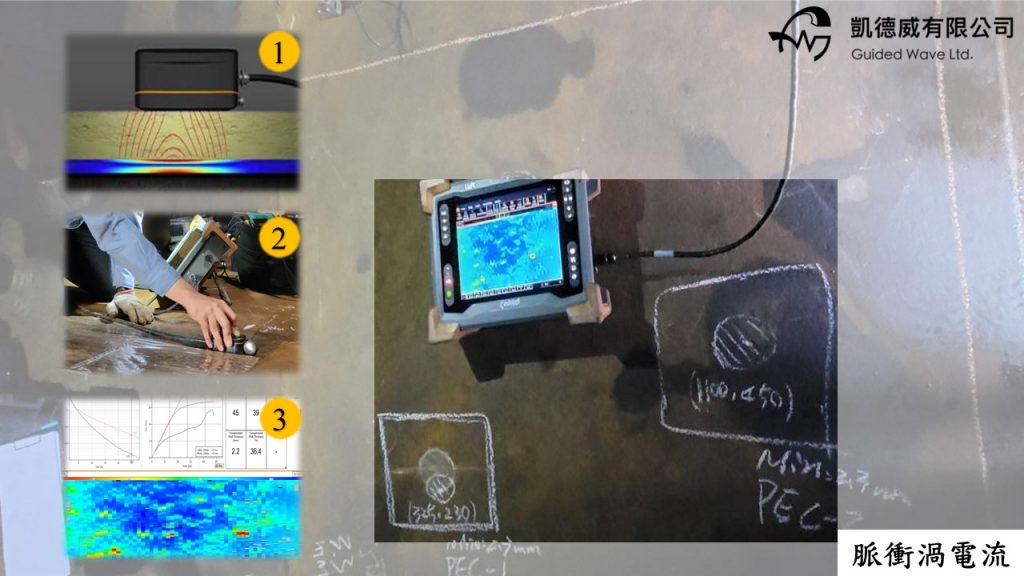

The scanning plan;

1.PEC analyzes the transient eddy current in a conductive component after a sharp

electromagnetic transition.

2.Drawing straight lines onto the plate was an important part before making any contact. It also helped correspond defects’ positions and led inspector while scanning.

3.After the evaluation, two corrosions were found and marked on the plate.

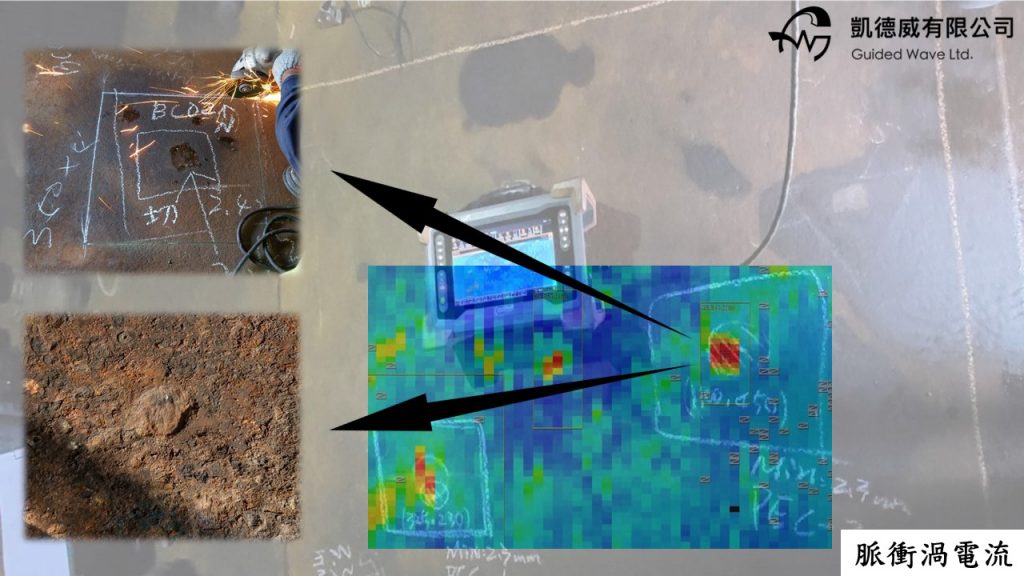

Analysis;

From the C-scan & system’s algorithm, the remaining wall thickness are 2.2mm and 2.3mm respectively behind the plate (soil side). Pictures showed sever corrosion after removal. Above all, we had confirmed that PEC was a suitable technique for finding defects where people couldn’t visually assess while quantifying defect depth at the same time, minimizing the risk of leakage.